This is based on a real case study, though certain details have been amended for confidentiality. For those who may recognize the actual project(s), kindly refrain from mentioning them here.

1) Project Background

Structure: X-storey mixed-use high-rise (retail + serviced apartments),

Location: Coastal city, soft clay soil with deep bored pile foundations,

Stage: Superstructure completed up to Level X.

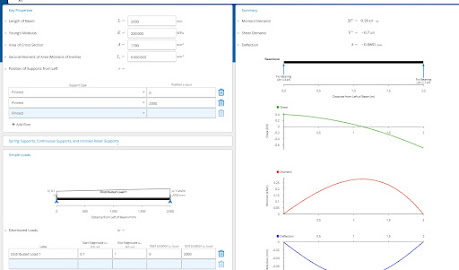

During routine QA checks, the structural consultant noticed unusual deflections and hairline cracks on transfer beams supporting Levels X–X (retail podium transitioning to apartment floors).

2) Red Flags Raised

a) Laser survey showed mid-span deflection of 30 mm after only 6 months, double the predicted value (15 mm),

b) Non-linear structural analysis suggested risk of progressive collapse if additional floors were added without intervention.

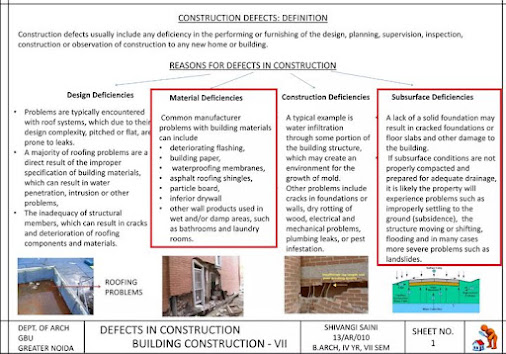

3) RCA

a) As-built rebar placement in transfer beams was incorrect (laps at critical zones, reducing effective moment capacity),

b) Concrete cube strengths were acceptable, but site pour sequence created cold joints,

c) The combination of poor detailing + construction error led to reduced structural safety margins,

Potential Consequences: Failure of transfer beams → collapse of multiple floors above → fatalities + total project shutdown.

4) Emergency Actions

a) Immediate Stop-Work Order issued by Consultant and Client,

b) Evacuation of workers from Levels X–X,

c) Shoring/Propping with heavy-duty steel towers installed below affected beams to temporarily relieve stress.

5) The Solution (Technical Masterstroke)

After a tense 2-week design workshop involving the Consultant, Contractor, and an independent structural expert, the following remedial engineering strategies were adopted :

a) Carbon Fiber Reinforced Polymer (CFRP) Strengthening - applied CFRP laminates to the soffit of transfer beams to enhance flexural capacity and CFRP wrapping around beam sides to improve shear resistance,

b) Post-Tensioning Retrofits - Installed external post-tensioning tendons anchored at beam ends, applied calculated pre-stressing force to reduce service loads carried by original rebar.

c) High-Strength Grouting of Cold Joints - epoxy injection into cold joints and cracks to restore monolithic action.

d) Structural Health Monitoring (SHM) - embedded strain gauges + tilt meters to monitor deflections and load redistribution in real time with daily monitoring reports to Consultant and Client.

6) Verification

a) Load tests conducted with water ballast tanks at Level X - structure performed within predicted limits,

b) Survey showed deflection recovered by 12 mm and stabilized within safe thresholds,

c) Independent checker certified remedial works as safe and durable.

7) Outcome

a) Construction resumed with minimal delay (~3 months vs total project loss),

b) Building successfully completed and now stands proudly, housing over 1,000 residents and businesses,

c) Client avoided catastrophic collapse, lawsuits, and financial ruin.

Instead of demolition and rebuild, which would cost millions and years, the engineers used cutting-edge strengthening technology (CFRP + post-tensioning) - something rarely attempted at this scale in the region.

The professionalism - stop-work order, transparent communication, third-party verification, and modern monitoring - set a benchmark for crisis management in construction.

What could have been a tragedy turned into a showcase of engineering brilliance.

8) Lessons Learned

a) Always verify reinforcement placement - don’t just rely on bar bending schedules,

b) Cold joints in critical structural members require strict monitoring and approval,

c) Advanced materials like CFRP and post-tension retrofits can be life-saving when conventional repairs are inadequate.